Tel : 0086-021-60880117

Tel : 0086-021-60880117

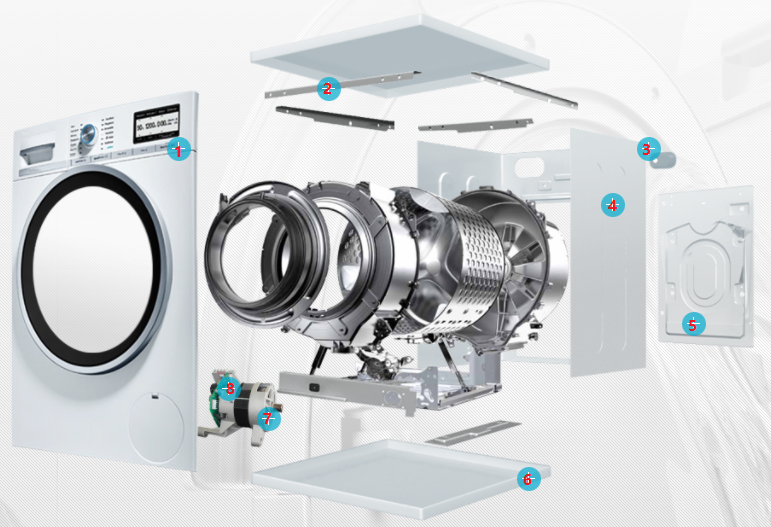

Washing machine is one of the five essential appliances and is composed of casing, washing and drying tube(or separated washing and drying tubs), transmission and controlling system, and for some of the washing machines, heating unit. It is mainly used in damp environment. The development trend of washing machine is larger capacity and multi-functional, and accordingly it uses materials to achieve multi-functions.

1. Front panel

Part requirements: Flat .

Material Requirements:Look good with whole washer.

Recommended materials:

|

Part No. |

Part No. |

Type |

Grade |

Size(mm) |

Suggestion |

|

1 |

Front panel |

General cold rolled steel |

SPCC |

0.8 |

Spray painting after parkerising |

2. Casing Reinforcement

Part requirements: Solid and durable; Absorbing shock and noise.

Material Requirements:Proper thickness to provide stable working environment.

Recommended materials:

|

Part No. |

Part No. |

Type |

Grade |

Size(mm) |

Suggestion |

|

2 |

Casing Reinforcement |

General cold rolled steel |

SPCC |

1.5 |

Spray painting after parkerising |

3. Electromagnetic valve holder

Part requirements: Solid and durable; Absorbing shock and noise.

Material Requirements:Proper thickness to provide stable working environment.

Recommended materials:

|

Part No. |

Part No. |

Type |

Grade |

Size(mm) |

Suggestion |

|

3 |

Electromagnetic valve holder |

General cold rolled steel |

SPCC |

0.8 |

Spray painting after parkerising |

4. Front/Back U casing

Part requirements: Work well in damp environment; Flat .

Material Requirements:Corrosion-resistance; Superb surface quality; Good shape; High yield strength; Strict control of carbon content and skin rolling process .

Recommended materials:

|

Part No. |

Part No. |

Type |

Grade |

Size(mm) |

Suggestion |

|

4 |

Front/Back U casing |

Prepainted steel |

0.5-0.6 |

Spray painting after parkerising |

|

|

Hot-Dip galvanized steel |

DX51D+Z |

0.5-0.6 |

|

5. Back cover

Part requirements: Flat .

Material Requirements:Look good with whole washer.

Recommended materials:

|

Part No. |

Part No. |

Type |

Grade |

Size(mm) |

Suggestion |

|

5 |

Back cover |

General cold rolled steel |

SPCC |

0.8 |

Spray painting after parkerising |

6. Base plate

Part requirements: Work well in damp environment; Longer service life.

Material Requirements:Superb drawing quality; No surface in the drawing process.

Recommended materials:

|

Part No. |

Part No. |

Type |

Grade |

Size(mm) |

Specialty |

|

6 |

Base plate |

Hot-Dip galvanized steel |

DX54D+Z |

1.25 |

Anti-fingerprinting; High corrosion-resistance. |

7. Motor

Part requirements: Smaller; Energy-efficient; Low noise level.

Material requirements: Electrical steel with good lamination performance and high efficiency.

Recommended materials:

|

Part No. |

Part No. |

Type |

Grade |

Size(mm) |

Specialty |

|

7 |

Motor |

Electrical steel |

B50AE-2 |

0.5 |

High-efficiency |

|

0.35,0.5 |

|

8. Motor casing

Part requirements:Fit the motor ; Noise absorption.

Material requirements: Superb drawing quality; No fracture in the drawing process.

Recommended materials:

|

Part No. |

Part No. |

Type |

Grade |

Size(mm) |

Specialty |

|

8 |

Motor casing |

Hot-dip galvanized steel |

DX53D+Z |

0.6-1.2 |

High lubricating; Oil-free drawing |

|

DX53D+Z |

0.6-1.2 |

Chrome-free passivation; Ordinary drawing |