Tel : 0086-021-60880117

Tel : 0086-021-60880117

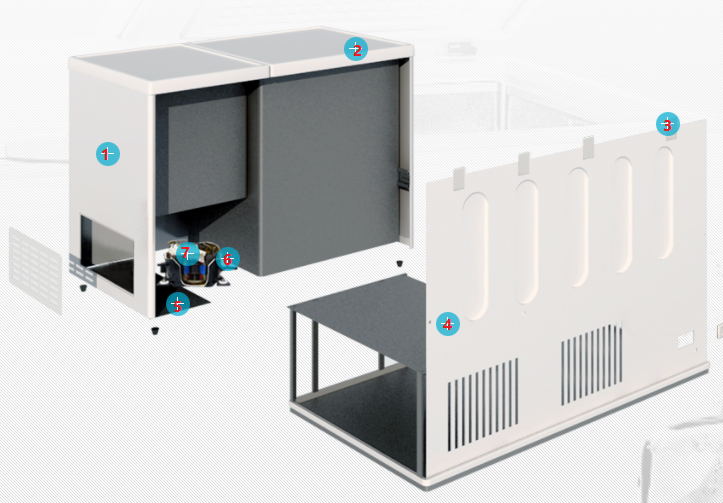

Originally used in shopping malls, supermarkets, and hotels, freezer is popular in households now. It is used in a gentle environments and has similar structure as refrigerator. The trend is to use thinner sheet with high strength.

1. Case Side Plate

Part requirements: Proper stiffness, movable; Flat and straight; Proper hardness and no deformation after foaming.

Material Requirements: Flat and Straight; Thickness≥0.35mm; Hardness HRB≥40

Recommended materials:

|

Part No. |

Part No. |

Type |

Grade |

Size(mm) |

Specialty |

|

1 |

Case Side Plate |

General cold rolled steel |

BLC-JD2 |

0.4-0.5 |

Spray painting after parkerizing |

|

Prepainted Steel |

TSECD |

0.4-0.5 |

Oil-resistant coating; |

||

|

TDX52+Z |

2. Door panel

Part requirements: Flat and straight; Proper hardness and no deformation after foaming.

Material Requirements: Flat and straight; Hardness HRB≥40

Recommended materials:

|

Part No. |

Part No. |

Type |

Grade |

Size(mm) |

Specialty |

|

2 |

Door Panel |

General cold rolled steel |

BLC-JD2 |

0.4-0.5 |

Spray painting after parkerizing |

|

Door panel |

TSECD |

0.4-0.5 |

Oil-resistant coating; |

||

|

TDX52+Z |

3. Hinge Plate

Part requirements: Proper strength and stiffness; No deformation when bearing weight.

Material Requirements: Flat ; Y.S ≥300MPa.

Recommended materials:

|

Part No. |

Part No. |

Type |

Grade |

Size(mm) |

Specialty |

|

3 |

Hinge Plate |

General cold rolled steel |

SPCC |

2.0 |

Spray painting after parkerizing |

4. Case Back Plate

Part requirements: Flat and Straight, no exceptional requirement.

Material Requirements: Flat and straight; Easy for assembly.

Recommended materials:

|

Part No. |

Part No. |

Type |

Grade |

Size(mm) |

Specialty |

|

4 |

Case Back Plate |

General cold rolled steel |

BLC-JD2 |

0.4-0.5 |

Spray painting after parkerizing |

|

Door panel |

TSECD |

0.4-0.5 |

Oil-resistant coating; |

||

|

TDX52+Z |

5. Base Plate

Part requirements: Work well in moist environment.

Material Requirements: Corrosion-resistance;Good forming performance.

Recommended materials:

|

Part No. |

Part No. |

Type |

Grade |

Size(mm) |

Specialty |

|

3 |

Base Plate |

General cold rolled steel |

SPCC |

1.5 |

Spray painting after parkerizing |

6. Compressor Motor

Part requirements:Low noise level;Smaller; Energy-efficient;

Material requirements: Small thickness tolerance; high magnetic induction; Low iron loss;Flatness

Recommended materials:

|

Part No. |

Part No. |

Type |

Grade |

Size(mm) |

Specialty |

|

6 |

Compressor Motor |

Electrical steel |

B50AE-3 |

0.5 |

High-efficiency |

|

environmental friendly |

|||||

7. Compressor Case

Part requirements: Improved welding and coating property;Pressure-resistant

Material requirements: Deep drawing quality; Uniform performance.

Recommended materials:

|

Part No. |

Part No. |

Type |

Grade |

Size(mm) |

|

7 |

Compressor Case |

Pickled steel |

SPHD,SPHE |

2.6-4 |